Enterprise resource planning (ERP) is a powerful technology for syncing critical supply chain transactions and records. It’s designed to keep transactions integrated, so customer orders, invoices, inventory, and other elements remain consistent. And it does a great job as far as that goes.

Yet leveraging an integrated ERP system to make strategic and operational decisions that result in a more efficient and effective value network remains an elusive goal. That’s because the ERP’s underlying tables are inscrutable to business users—most of whom are not familiar with an ERP system’s complexity—so searching, gathering, and translating ERP data into useful business insights remains a daunting task for them.

Other types of software tools exist specifically to help address this challenge, but they each struggle with their own shortcomings. For instance:

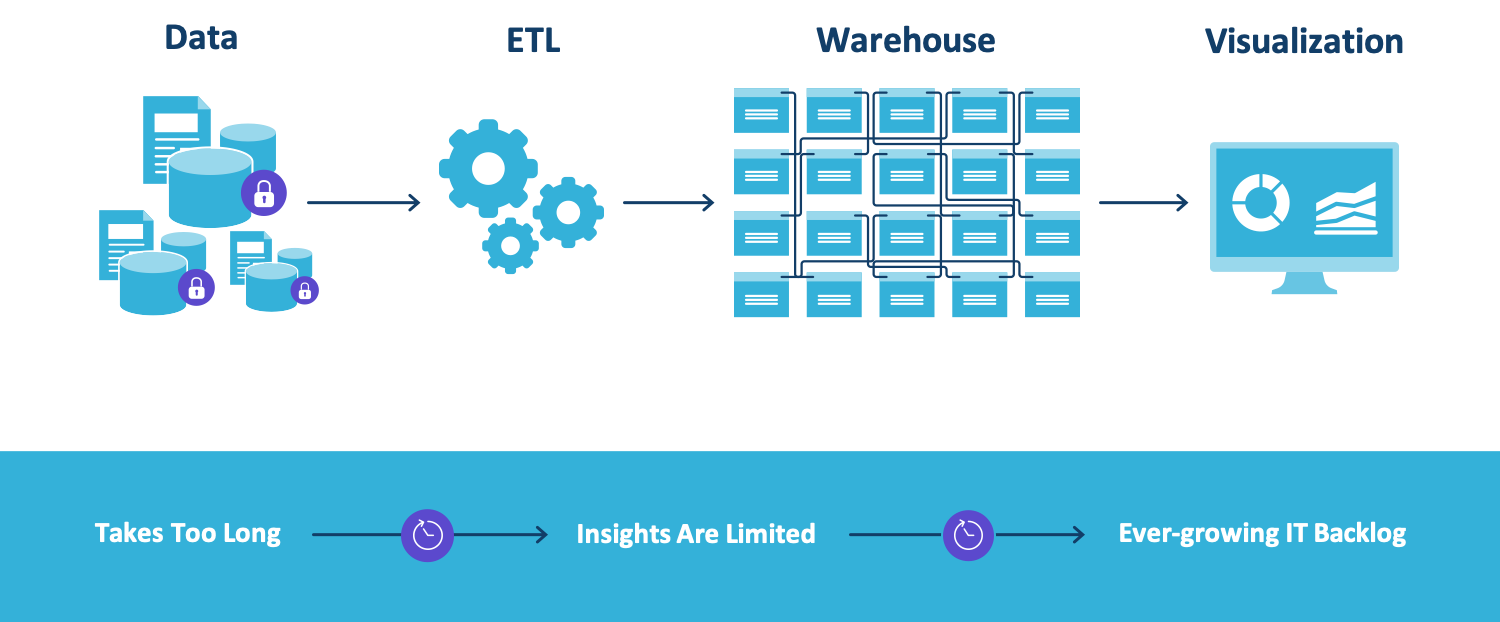

Business intelligence (BI) tools only answer the questions users had 3-4 months ago because it takes that long for scarce IT resources to build out the needed analytics infrastructure. That’s why these tools require prior planning and decisions made in advance regarding which data to include in an analysis, how to aggregate the data, how to present the data, etc. Plus, a substantial amount of time and cost is involved in building the data warehouse structure to support the BI tool, wrangling ERP data into that structure, and building or configuring an interface for the end user.

Advanced planning and scheduling (APS) tools help optimally allocate raw materials, production, and distribution capacity to balance demand and supply, with the goal of providing the necessary service with the least cost. Unfortunately, every APS plan results in hundreds of exceptions which are difficult to sort and prioritize, and—to add to the confusion—many exceptions refer to the same issue. APS systems also are not very effective at highlighting root causes.

Other IT tools that automate business processes and track work performance help trace shipments, monitor machine performance on the shop floor, and track movements in the warehouse. The challenge with this type of information is that it usually isn’t provided in a holistic business context, so users are left without an understanding of the root cause of problems. As a result, they’re unable to make well-informed, timely decisions to rectify the issues before it’s too late.

The result? Justifiably impatient and under-pressure supply chain users are forced to:

- rely on—and wait in line for—IT resources already at capacity;

- try to extract the correct data set from the muddle of systems outlined above;

- manipulate data for hours to get the answers they need, if they can get them at all; and

- leverage insights that—once they’re finally obtained—are very limited in their scope and usefulness.

The problem with data warehouse-based analytics.

Clearly this ERP-based process doesn’t mesh with the real needs of business users who face an endless, growing stream of new, operational and strategic questions that need to be answered every day. Their decision cycle needs to be much faster and able to leverage clear, definitive, and timely insights.

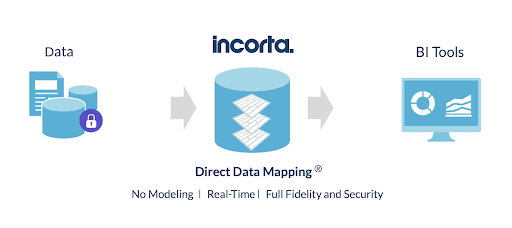

And that’s exactly what Incorta does.

Incorta Gives Supply Chain Users Answers They Need, When They Need Them

With Incorta, you now can answer questions you couldn’t answer before using only your ERP, APS, and legacy BI tools.

Incorta’s breakthrough technology eliminates the most time-consuming IT activities involved in creating supply chain insights, and easily supports an ever-accelerating decision cycle of detecting challenges, diagnosing root causes, and directing the next-best-actions in relevant time.

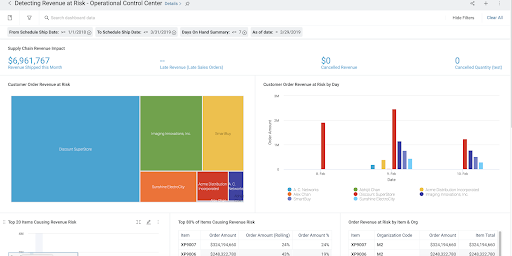

For example, the “Revenue at Risk” dashboard below enables business users to identify critical customer orders that need immediate attention. The corrective action can be as simple as calling the customer in advance to inform them of available product alternatives, offering a discount on the next order, or fulfilling the order from an alternate location.

Incorta’s “Revenue at Risk” dashboard instantly highlights customer orders at risk, their root causes, and the actions needed.

By using Incorta to put these kinds of insights at the fingertips of decision makers—along with the problem’s root cause and the suggested best course of action—you can positively impact the business in a variety of ways.

- Maintain a high level of customer satisfaction

- Avoid customer-imposed fines

- Minimize excess and expedited freight

- Avoid unnecessary manufacturing changeovers

- Maximize inventory utilization across the supply network

With Incorta, you have results in days, not months; can empower users to leverage truly self-service analytics; and make real use of data that is always on, always current, and always complete—down to the lowest level of detail across every dimension.

Incorta delivers dashboards like this one in just days, so business users can get the answers they need in only seconds.

The net-net? Incorta empowers you to keep pace with the cycle of business challenges, so you can close the gap between supply chain planning and supply chain execution.

Ready to learn more? Download the Data Modeling Sabotages Supply Chain Analytics eBook.